With toothpicks and miniature cups of glue priced at $500 apiece, Wyoming Intermediate School fifth-graders quickly learned that building a bridge with a $100,000 faux budget was no easy task.

“This costs a lot of money and it’s extra hard,” said Arieanna Sheets, who served as project manager in her group, named Wolf Pack Bridge Company. “It takes teamwork to build a bridge.”

Social studies teacher Wendy Kiel decided to turn an economics unit into a real-life project on business ownership. Good financing, planning, budgeting, organization and collaboration were necessary to build a sturdy bridge by the due date and without going in the red.

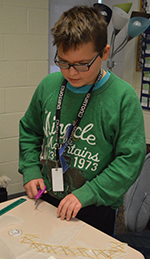

Students pieced together the tiny wooden beams and gluey “cement” by using blueprints to design trusses and bridge roads in groups, with members assigned to the roles of contractor, materials handler, architect and project manager.

“I was trying to tell them we need to get this done today,” said Tate Staffen, who worked as a project accountant, about helping his group stay on task. Tate and his group met their goals as the first team to complete the bridge’s trusses and road. By the end of class, they were ready to assemble it into a final structure. Tate explained how his group set aside funds to pay for extra materials in case of an emergency.

“It’s easier when you work together,” said Gonzalo Ordonez, the group’s architect.

Tate and Gonzalo’s company wasn’t the only one to have a good day: Kiel awarded all students with an extra bonus for cleaning up efficiently.

How to Build a Toothpick Bridge

|

Not as Easy As It Looks

The project led to a few “meltdowns” on the way to success, as groups realized they were running out of time and money, Kiel said. Students had to learn hard lessons on what happens when you lose your toothpicks or waste the glue: fork over another check.

“The money’s probably been the biggest problem,” said Jacob Herrema, project manager for his group, Steel Machine Inc.

But students were often awarded with bonuses for good work, or got to take advantage of material sales, helping them stay within budget.

Calling teamwork a “big fifth-grade standard,” Kiel said students had to understand fees, fines, bonuses, meeting deadlines and setting priorities as a group to make steady progress on their bridges.

After completing the project, the students tested their pieces’ durability by hanging weights off them to see how well they stayed intact. Bridges proved strong, with some supporting more than eight pounds of weight.

CONNECT