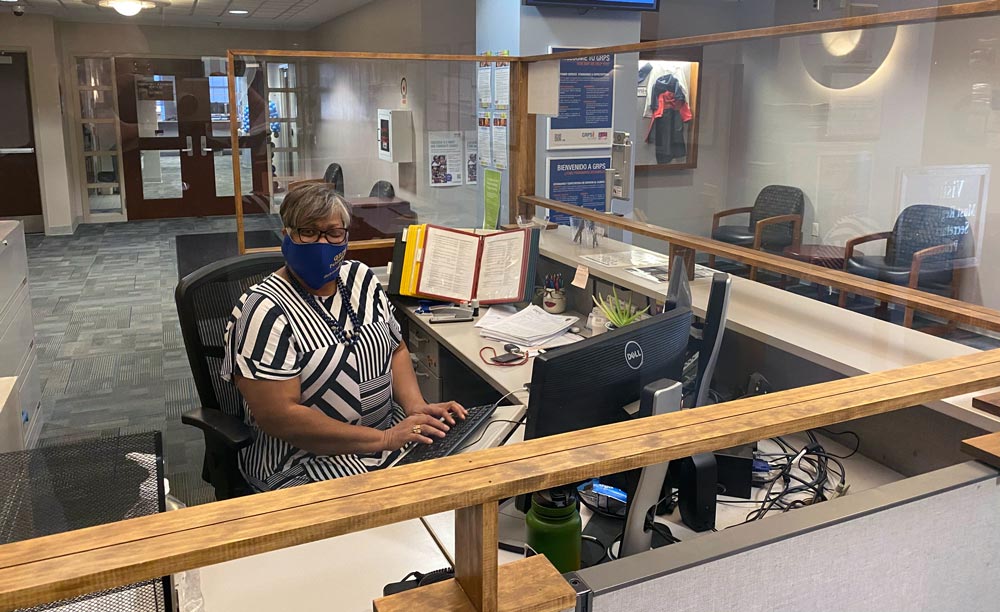

Grand Rapids — They call them sneeze guards — the protective Plexiglas barriers on desks and countertops and more that separate employees from visitors.

But really, says Brad Bennett, carpentry and painting maintenance supervisor for Grand Rapids Public Schools, that term doesn’t do them justice.

“When I hear ‘sneeze guards,’” he says with a chuckle, “I think salad bars. These are not that.”

By these he means the hundreds of barriers crafted this summer and fall by Brad Lehnert, a carpenter-craftsman who sports a mean salt-and-pepper Fu Manchu but has a quiet disposition, including a preference for getting the job done over talking about it.

Still, there’s an evident pride in what he was able to accomplish in a short amount of time, and a sense of satisfaction in the fact that his work is keeping his fellow district employees safer.

And Bennett, his supervisor, is more than happy to talk on Lehnert’s behalf.

“Brad had maybe four to six weeks to produce hundreds of these barriers,” Bennett recalls. “We did some research on what it would cost to buy them, and we decided we could do it for about a quarter of the price. But it was a lot of work, a lot of work.”

At this Lehnert just smiles and adds, “It was all day, every day for quite a while.”

Larry Johnson, chief of staff for GRPS, still stands amazed at what was accomplished by Lehnert, with Bennett lending a hand when he was able.

“Their attention to detail,” he says, “and the quick turnaround was nothing short of a miracle for the district.”

A Massive Collection of Raw Materials

The barriers became necessary in a time of COVID-19 to protect the people behind them — mainly GRPS secretaries and other office workers who are public-facing and who had been working in person — from sneezes, coughs and the normal exhalations a visitor might present, just as in recent months banks, grocery stores and more have worked to protect their employees with such barriers.

The district used federal CARES Act money to pay for the sizable project, which at last count had placed the barriers in 52 of 57 GRPS buildings. Many of the buildings needed multiple barriers, and one significant challenge from the start was that every desk is different, and so every barrier ended up being different.

But each one started with a massive collection of raw materials.

Skids full of 4-by-8 sheets of Plexiglas; mountains of what the Brads call “one by” (the pine used to frame the barriers); gallons of the dark walnut stain and urethane Lehnert applied by hand to each piece of pine on each barrier; and thousands of the number-six Phillips screws that Lehnert bought up by the boxful from local hardware stores, and screwed in with his cordless, 12-volt Milwaukee as he built the frames around the Plexiglas.

Lehnert also loaded up the finished barriers into a GRPS van and delivered and installed them in empty schools all summer.

“There were times coming in to work where I wasn’t really looking forward to building more barriers,” he says, “but what kept me going was knowing how important this project was to the people I work with. That was a big deal.”

Bennett figures all told Lehnert’s efforts saved the district $30,000 or more versus what it would have cost to buy the products.

“And,” he says with a proud grin, “they look better too.”

Lehnert, a carpenter for four decades now, doesn’t say anything. But his gaiter moves a little around his mouth and his eyes sparkle as he smiles in agreement.